WEDM Hierarchical Structure Explained

Publication Date:2025-04-26 16:28:16

Publication Date:2025-04-26 16:28:16 Author:Kingred

Author:KingredSmart WEDM machines come in different forms. Could be aesthetic and awe-inspiring. But do you really know what defines the functionality and what drives your costs? It’s impossible to know, if you just look the machine intuitively.

In recent years, manufacturers are very obsessed with labeling their machines with words like “automatic”, “intelligent”, “smart”, etc. As we talked about in WEDM in Industry 4.0, that’s because they are integrating a lot of advanced technologies into their mechanical systems. Good news, they make the machine more capable. Bad news, the cost of the machines is raised.

Good or bad, we are going to break down a “smart” or “intelligent” wire cut electrical discharge machining (WEDM) machine. Let’s take Kingred WEDM machine KD400ZL as our model.

Disclaimer: by “hierarchical”, we don’t mean superiority. It's mainly about dependency, functional roles, life cycles and cost structure. Also, there are some concepts that are intangible but tightly related to these layers. Some concepts and parts span multiple layers, but we’ll keep them where they are relevant the best. Most importantly, this is not the only way of understanding a WEDM system.

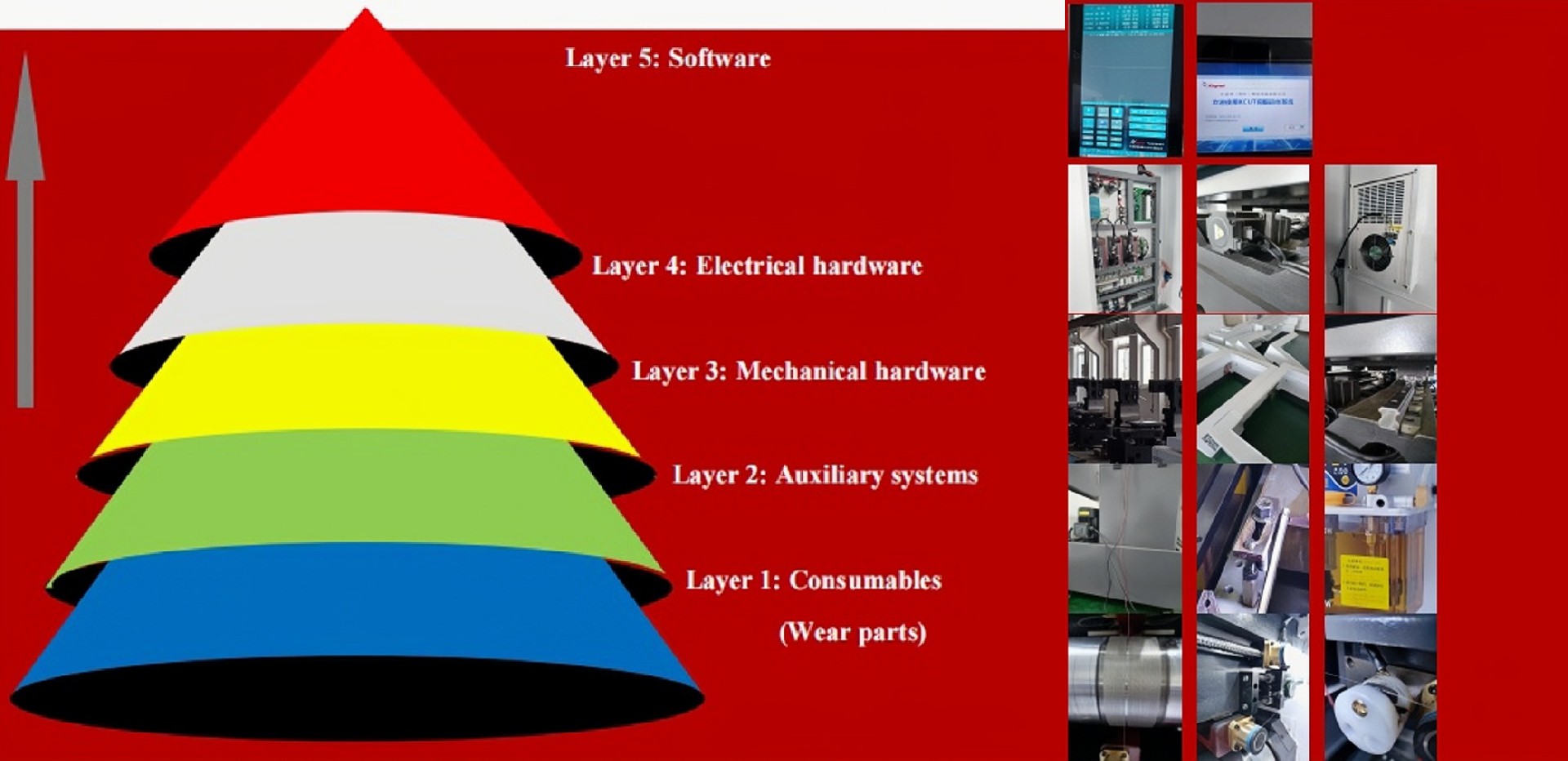

An intelligent WEDM machine is a highly integrated ecosystem, which can be broken down into 5 layers based primarily on dependency. In an essence, how much you know about this ecosystem technically determines how possible it is for you to predict how much value it can create for you in your market.

From bottom up, we get (1) consumables, (2) auxiliary systems, (3) mechanical hardware, (4) electrical hardware, and (5) software. Each layer can be further broken down based on different metrics. But why do we split components into these layers in the first place?

These layers are organized mainly by how they depend on each other. At the top, the digital software directs the whole system, but it relies on the electrical hardware and mechanical components to collaborate.

While the electrical and mechanical hardware executes the commands the software sends, it requires materials, energy, and maintenance.

Auxiliary systems are designed to be added or removed without affecting core systems.

So, at the bottom, consumables supply materials to sustain all layers, but they are just consumed passively. They are not programmable, they don’t process information, nor do they generate movements.

In summary, the software commands, the hardware executes, the auxiliary systems assist, and the consumables make it sustainable.