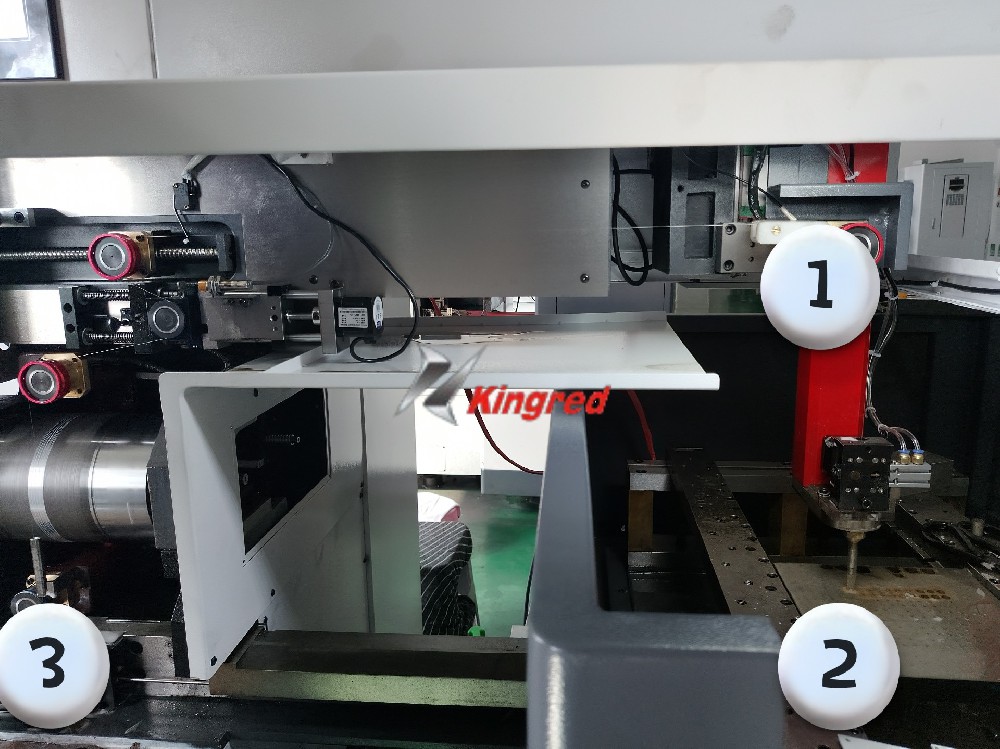

Side-Mounted Wire Drum with Integrated AWT System

Publication Date:2025-10-09 09:27:35

Publication Date:2025-10-09 09:27:35 Author:Kingred

Author:KingredIn KINGRED molybdenum wire EDM design, the wire storage spool is positioned on the machine's side rather than the back. This compact arrangement keeps the wire unit close to the mechanical frame, reducing vibration and saving workspace.

Technical Breakdown: Three 90° Turns in a Side-Mounted Wire Path

When integrating the AWT system, this side-mounted layout requires the wire to travel through three significant 90-degree turns.

a. At the upper guide wheel, the wire makes its first significant L-turn to enter the cutting zone with proper alignment.

b. At the lower guide wheel, the motorized system completes the second L-turn, keeping wire motion steady and controlled.

c. Finally, right below the wire storage spool, the wire makes a third L-turn, this time directed upward through a Z2-axis guiding tube. This upward turn is the most technically demanding part of the design, as it combines tight routing with precise tension control to support the automatic threading cycle.

User Benefits

This structure allows users to enjoy the space efficiency of a side-mounted design without losing threading reliability. The integration provides:

a. Compact overall machine footprint with full AWT capability;

b. Easier maintenance and spool replacement from the side;

c. Shorter wire path for lower wire loss and smoother feed;

d. Solid automatic threading performance, even after wire breakage during long runs.

In summary, this design transforms the side-mounted structure into a functional advantage, combining compactness, convenience, and advanced automation.